Well, we are at the point where I have the floor and walls done.

First, the floor is done, primarily. With self stick tiles there is always a chance a few of them will bow and bubble. We’ve had uncharacteristic 90F days, and it did loosen some of them. I will be using a dab of liquid nails to keep them down. That’s worked for me in the past with no issues. I lived for 7 years in a double wide trailer on a floor I put tiles like this down this way, and it looked the same when I moved out as when I put it in.

Doing a basket weave pattern with the flooring was perfect. It really hid the cheapness of the tiles. Honestly, this was an easy installation. I did have to wear knee pads as my knees can’t take floor work that easy, but I am happy with how it came out.

The walls? That was more frustrating. Apparently you need some H channel to put paneling up, so it slots each side of the touching panels together. The H channel available at Lowes where I bought this paneling, is not for this kind of paneling, but a slightly thinner white bathroom panel. I spent days searching every corner of the internet, and I couldn’t find it. I even tried that H channel with these paneling to see if I could retro fit it between the panels. No dice.

Instead I looked for any surface stick option. I tried stick on molding. It did not stick. I tried stick on edging for MDF shelving. It did not stick. I tried superglue to help any of these options to stick. It did not stick. I used 99% isopropyl alcohol on the seams, but even so, nothing stuck.

At this point I was sure that the surface of the cheap paneling I was using was some sort of secret non stick material that NASA should be notified of. Even epoxy did not stick to it. Literally nothing stuck on the long vertical lines where the two panels met. I tried everything.

After some hair pulling and soul searching, I reminded the inner evil voice of my father that likes to tell me I am screwing up, that this was just a fucking shed, so we were going the full cheap garbage route on this. The only way to fix this the “right” way, was to rip the paneling down, recut it to ensure the edges lined up with the 16 on center studs. However, I don’t own a table saw, and the perfect line up would be impossible and there would still be an issue, likely worse where the two edges me.

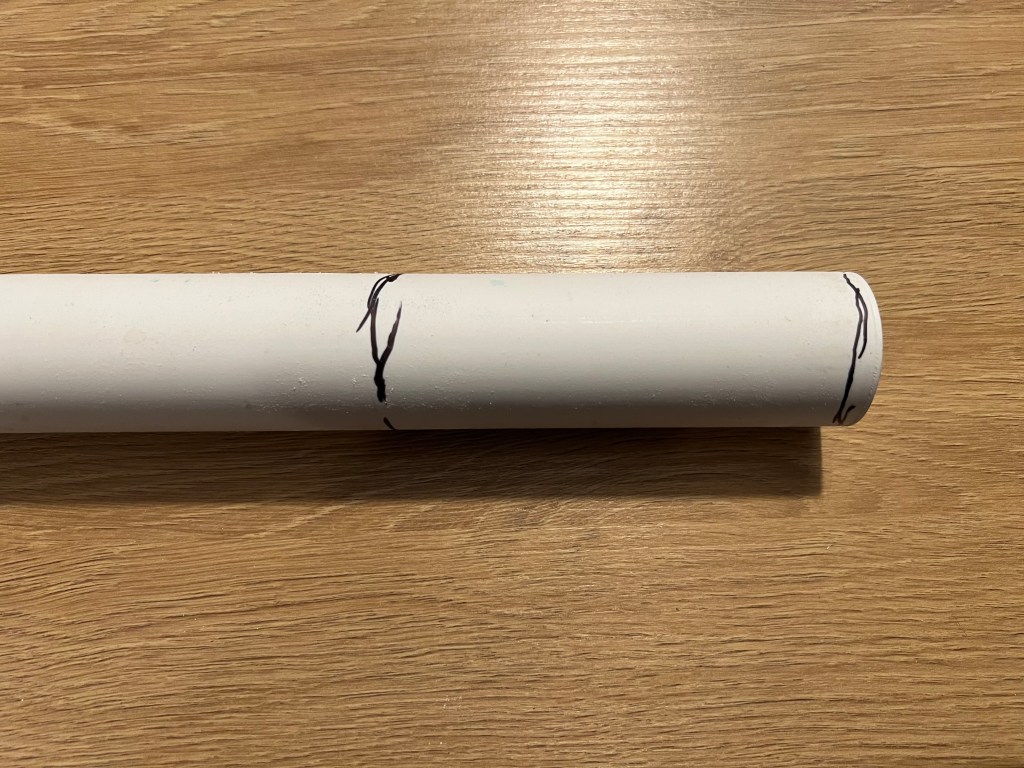

Instead, I used the only item that stuck to the paneling. White Gorilla brand duct tape. No other brand of duct tape would stick. I ran a line of duct tape down each join, imperfect as it was, and then a line of duct tape along the base for the cheap stick-it molding to adhere to.

This worked. I then added the big white roll of fake molding that you usually see self-stuck in bathrooms and kitchens in cheap rentals.

While this is certainly not the right way to do things, it is a way to do it. Once I have the shelves, the circus tent top and the artificial ivy and flowers in there, I think it won’t be as noticeable. What it does do is keep things together and that Gorilla duct tape is literally the only thing on this planet that stuck to the surface of that paneling.

In all honesty, nobody is going to see it but my wife and I, and as a place to put a workout machine, a workout bike, and some storage shelves? It’s okay. I’ll live with it.